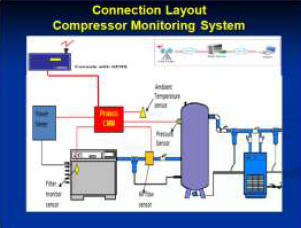

The measurement and logging of compressed air CFM is very important to ensuring a compressor is performing efficiently. It accurately estimate the amount of compressed air a particular compressor is producing, and this can related to the actual specification of what is the compressor was supposed to produce as per the manufacturer. In the past the measurement of flow was an inaccurate and very expensive exercise. Protech flow measurement technology has made thermal mass flow measurement very affordable and very easy to install for any organization, even for small systems. While the total accumulated air volume is important, the instantaneous lows tracked over time can reveal some system problems that can cause system performance deficiencies. For example, in a shift oriented plant with minimal weekend production the air flow at midnight on a Saturday might be a good indicator of system waste due to leakage and abandoned production machinery left to consume air when the machine is turned off.

The system measure the energy consumed KWH this is the key parameter in estimating the operation cost and also helps in the calculation of the KPI. These readings can be used in conjunction with flow measurement to keep track of system efficiency in terms of specific power The actual power consumption of a compressor is often a complete surprise. For example a recent measurement revealed a set of 55 kW rated air‐cooled screw compressors at an industrial site were consuming 70 kW each at full load and rated pressure. Still another 75 kW compressor was consuming 92 kW under the same conditions, and was consuming far more power than rated in the unloaded condition. This information was very useful to

then as assumed that the units would be consuming no more than nameplate rating like other similar electrical equipment.

The measure the load and unload of the compressor. Power draw when fully unloaded varies from about 60% of full load power to about 30% of full‐load power, depending on compressor design and on the length of time the compressor runs unloaded. This is a important parameter to monitor to help save energy. By logging this parameter necessary action can be taken to reduce unloading. It also calculated the amount of energy consumed during unloading.

So for higher pressure cut‐out set, we get less flow & at higher power consumption. For Less pressure cut out setting, we get more flow and at less power consumption. Please make use of these figures in industry "compress less & conserve more"If the pressure setting of a compressor is reduced by 1 kg/cm², the impact it will have on power consumption reduction by 6‐10%.

When the temperature of the inlet air to the compressor raises by 8°C the Power consumption increases by 2%.

This help in performing your maintenance work.

This tell you how much your air intake filter is clogged .If there is a clogging of the filter, it will effect the compression ratio and in turn will increase the power consumption of the compressor. As thumb rule "For every 0.355 Psi pressure drop increase across at the suction path due to choked filters, the compressor power consumption increases by about 2 % for the same output".

Protech CMS has made the monitoring of key compressed air performance indicators (KPI's) possible now than ever before. Compressed Air KPI's: With regard to the performance of compressed air powered compressed air equipment the most important indicator is definitely system pressure. But other aspects of the system are important as well. Knowing the cost of producing the air is important too, especially with rising electricity rates. This means the power consumption of compressors and associated equipment is an important factor. So too is a measurement of the compressed air flow produced by the air production equipment. Once power input and output flow are measured system specific power can be calculated which is an indicator of how efficiently your equipment produces air for a given energy unit input.

The Key Performance Indicator (KPI): kW/100 cfm The Protech CMS can produce reports on different areas, we recommend that managers focus on Key Performance Indicator (KPI): kW/100 cfm. This represents how much energy (in kW) is used to deliver how much air flow (cfm). The Protech CMS provides the tools required to monitor this KPI for each air compressor. This will also tell the cost of each CFM.

The system can be used as leak tester and also calculate the losses due to leak. This can be done by closing all the usage point and check how much CFM is lost. A distribution system of 100 PSI of pressure, running 12 hour a day with a leak of

Knowing the load on the DG will help in how efficiently you are using the DG and will know the cost per also helps in stopping pilferage of diesel. We can also know the quantity of fuel filled in generator, quantity consumed, running hours, alerts( if any) etc.

A management system for use oil is must in every workshop as this helps you raise your bottom line profits. Every drop of used oil is to be properly collected.

Day by day the tariff of water is going up. By only monitoring the pattern of use you can analyze how you can save water.

Monitors the following:

Water filled in the sump (Generally water tankers a bought this will give an idea how much water has been unloaded in the sump in Liters).

Temperature monitoring helps in saving energy of HVAC. If the setting is too low it is uncomfortable to the people in the building and also a waste of energy. By continuously

monitoring the temperature, we can surely save energy. Air condition are set to very low temperature, and not switched off after the business time . This saves 20%.

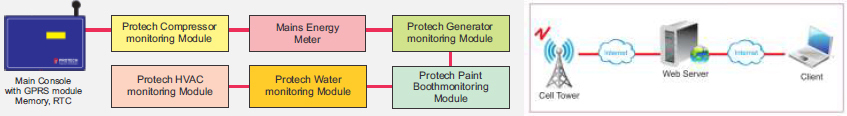

The system is cloud based system where in the data is collected and sent to the server the user can login and access the data and generate reports, and alerts will be sent if there are any deviations in the usage